Dear Customer,

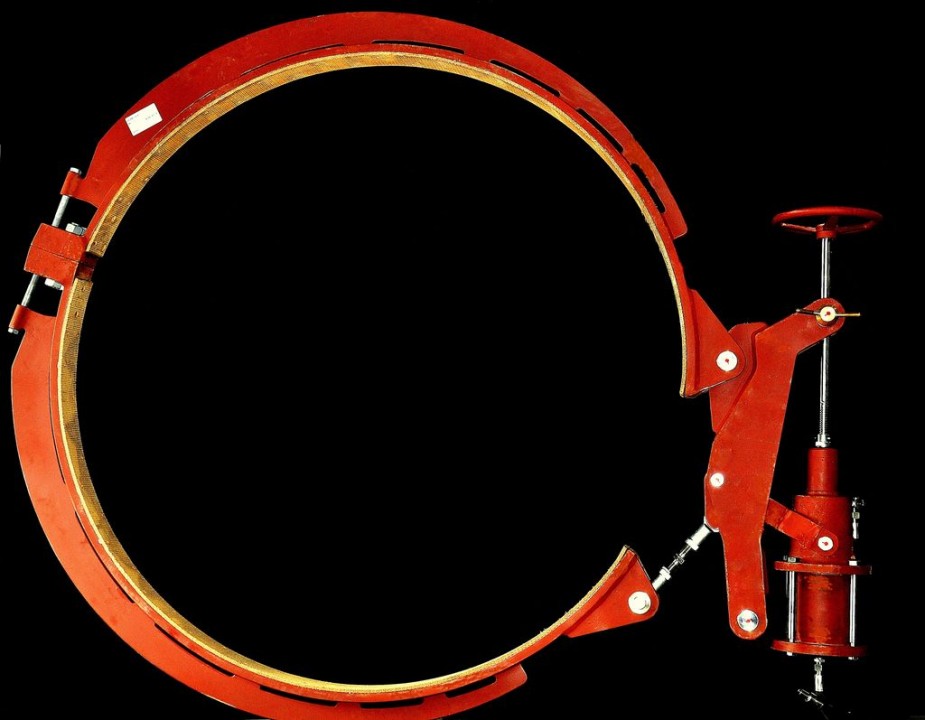

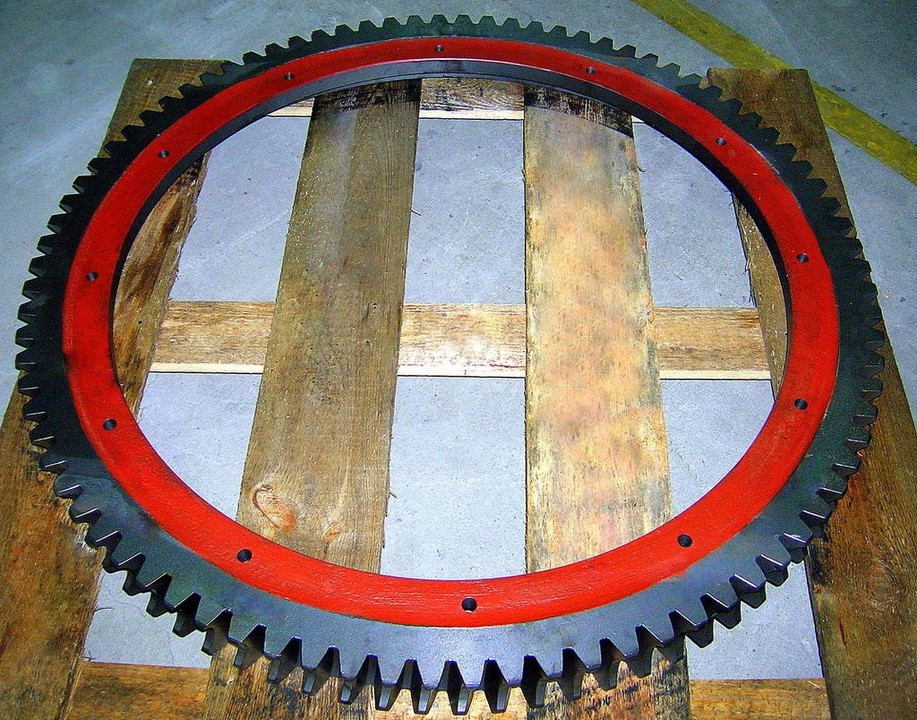

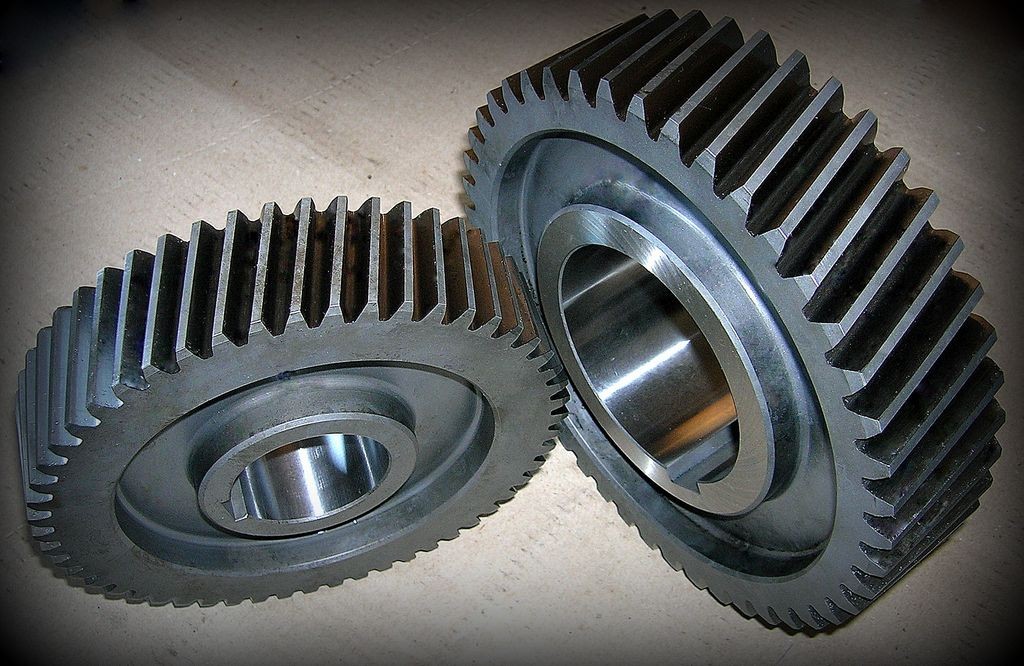

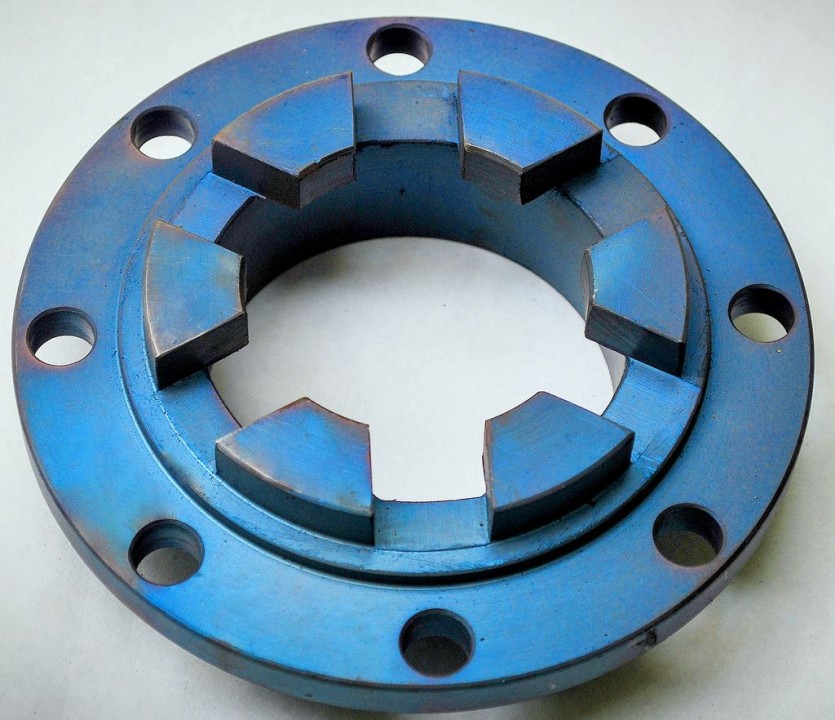

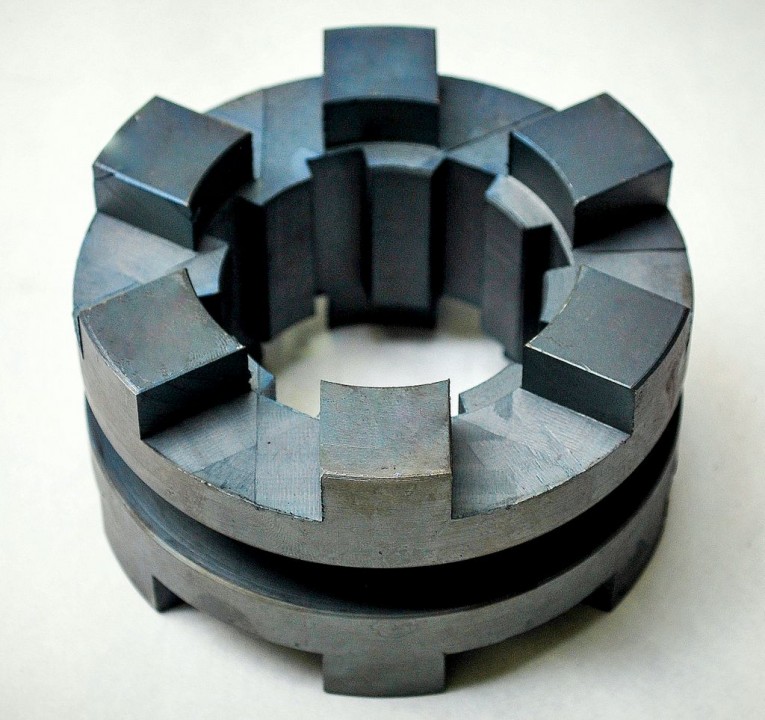

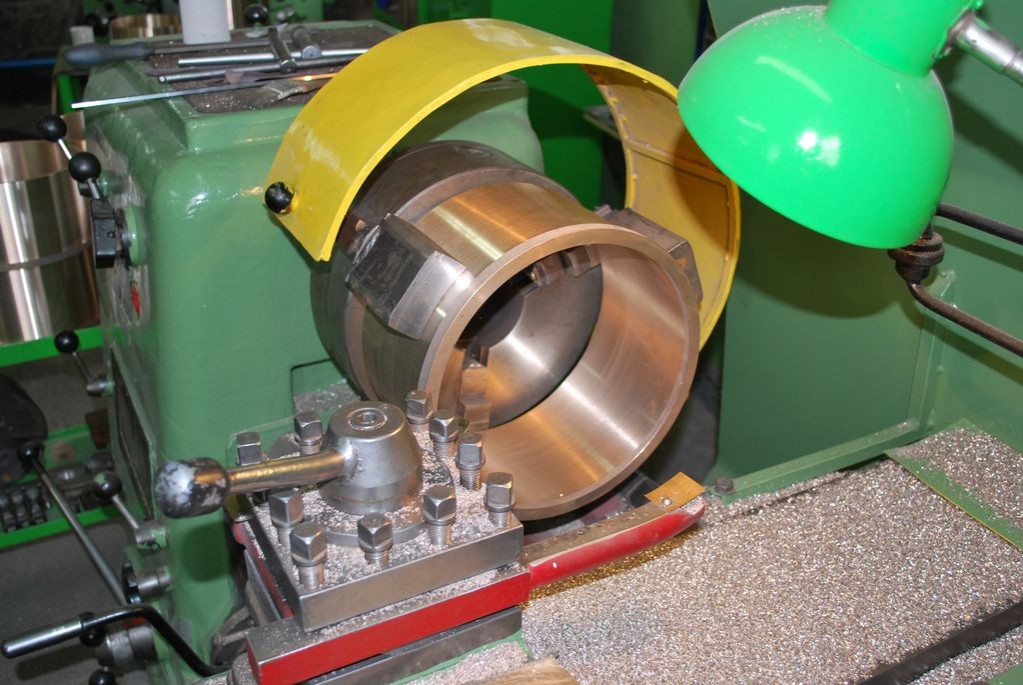

We are inviting you to cooperation with PPHU MAGMAR. Machining of metal is the main activity of our factory, especially in the range of spare parts and subassemblies production for marine (shipbuilding), paper and cellulose or power industries. Our factory is provided with various machines and equipment, which include turning lathes, milling, grinding and mill-boring machines. In November 2010 we successfully passed certified audit of Quality Management System in accordance with the requirements of ISO 9001. We are focusing on individual approach to customers’ needs. We offer one piece and series production by using either free issue or bought by ourselves materials.

Our strengths are high qualified, multi skilled resources and technical support for customer requirement. We permanently cooperate with demanding companies. We ensure delivery of high quality goods with customers’ expectation.

We Carry out low quantity and individual orders

We have an experienced and qualified staff

Quality control department ensures on our production process

We cooperate with home and international companies

About us

PPHU MAGMAR was established in 1997. From the beginning the company was focused on the production of parts used especially in shipbuilding, mining and hydro industry. In the initial time of activity the company was very limited due to the small area of production, the inability to source their own materials needed for production (production of assigned materials) and the constraints from the qualified staff.

Due to the increasing number of purchase orders the company began to develop its organizational structure. In 2007 was established PPHU MARKO, the twin company, which is owned by Magdalena Szmyt. Additionally, there were created the magazine on metallurgical products and quality control department. The development of the organization structure allowed for wider and more efficient business within the ongoing customer orders. This fact has contributed to increase of production area and quantity of machines and to employ qualified and skilled staff. In 2009, both companies have transferred its head office to Gniew, employing 28 people.

Trying to meet growing expectations of our customers, the companies implemented the quality management system according to PN-EN ISO 9001, they invest in development of machinery facilities and take any other actions to continuous improvement.

Quality control

Many years of experience guarantee to our customers a high standard of products and services.

The qualified staff and suitable machinery facilities ensure the product realization on time.

To our main services belong:

– turning,

– milling,

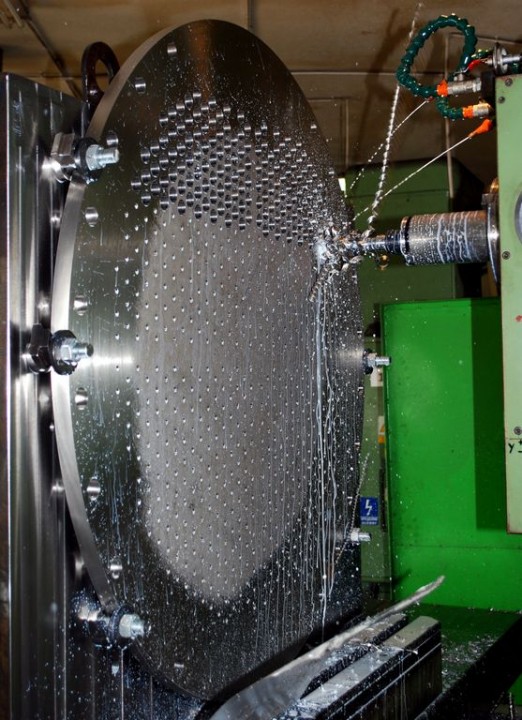

– boring,

– chiseling,

– grinding,

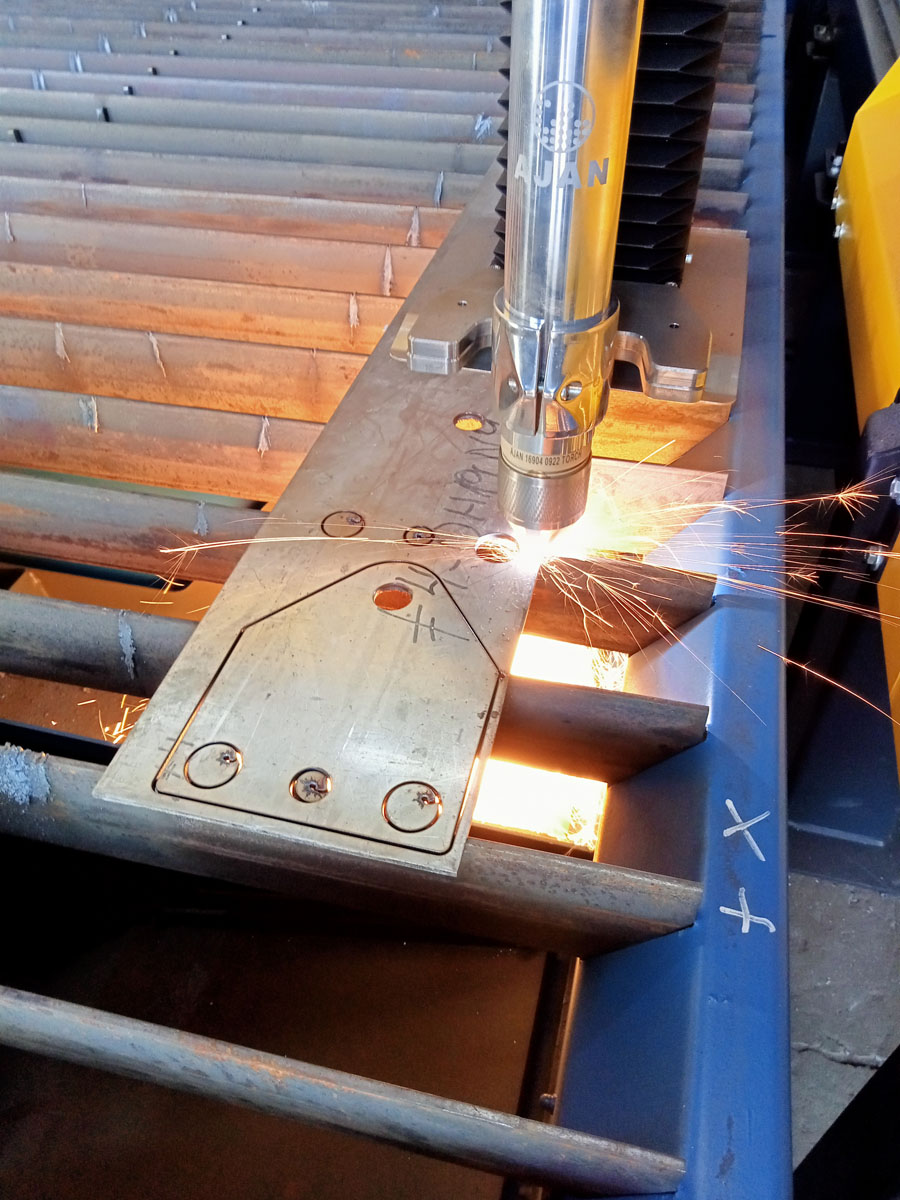

– mechanical and gas cutting,

– welding.

And the others:

– ironworks,

– machines and equipment repairs,

– production of new elements according to customer’s documentation.

Our capability

Conventional lathes

– max length 6000mm

– max Ø 500mm

Rotary lathe

– max Ø 1200mm

– max height 500mm

Conventional milling machines

– max length 1600mm

– max width 1250mm

– max height 1250mm

Gear milling machine

– max module 6

– max Ø 300mm

– max stroke 300

Boring machine

– max crosswise shift 1600mm

– max lengthwise shift 1250mm

– max vertical shift 1250mm

Slotting machines

max Ø 800mm

stroke 600mm

max length of groove 300mm

Flat-surface grynder

500x200mm

Grinding shafts and holes machines

– Ø external 250mm

– Ø internal 200mm

– Length of shaft 800mm

Cutting machines

– max Ø 220mm

Flame cutting machine

– max thickness 200mm

Plasma cutting machine

– max thickness 35mm

CNC drilling-milling machine WFM100

– spindle diameter Ø 100

– X – transverse travel 1500mm

– Y – vertical travel 1000mm

– Z – longitudinal travel 1000mm

– W – spindle extension 500mm

– Working surface of table 1100x1400mm

CNC lathe Feeler FTC-450

– max turning diameter Ø 450mm

– max length of the rolling 651mm

– spindle travel Ø 78

Quality control

We have our own measuring laboratory. The constant supervision of Quality Control Department ensures the highest quality of supplied and stored materials and the whole production process. The additional advantage is our Quality Controler’s qualification and skill to carry out the calibration process such measuring tools and non-destructive testing of welds by:

– visual,

– magnetic particle,

– penetration.

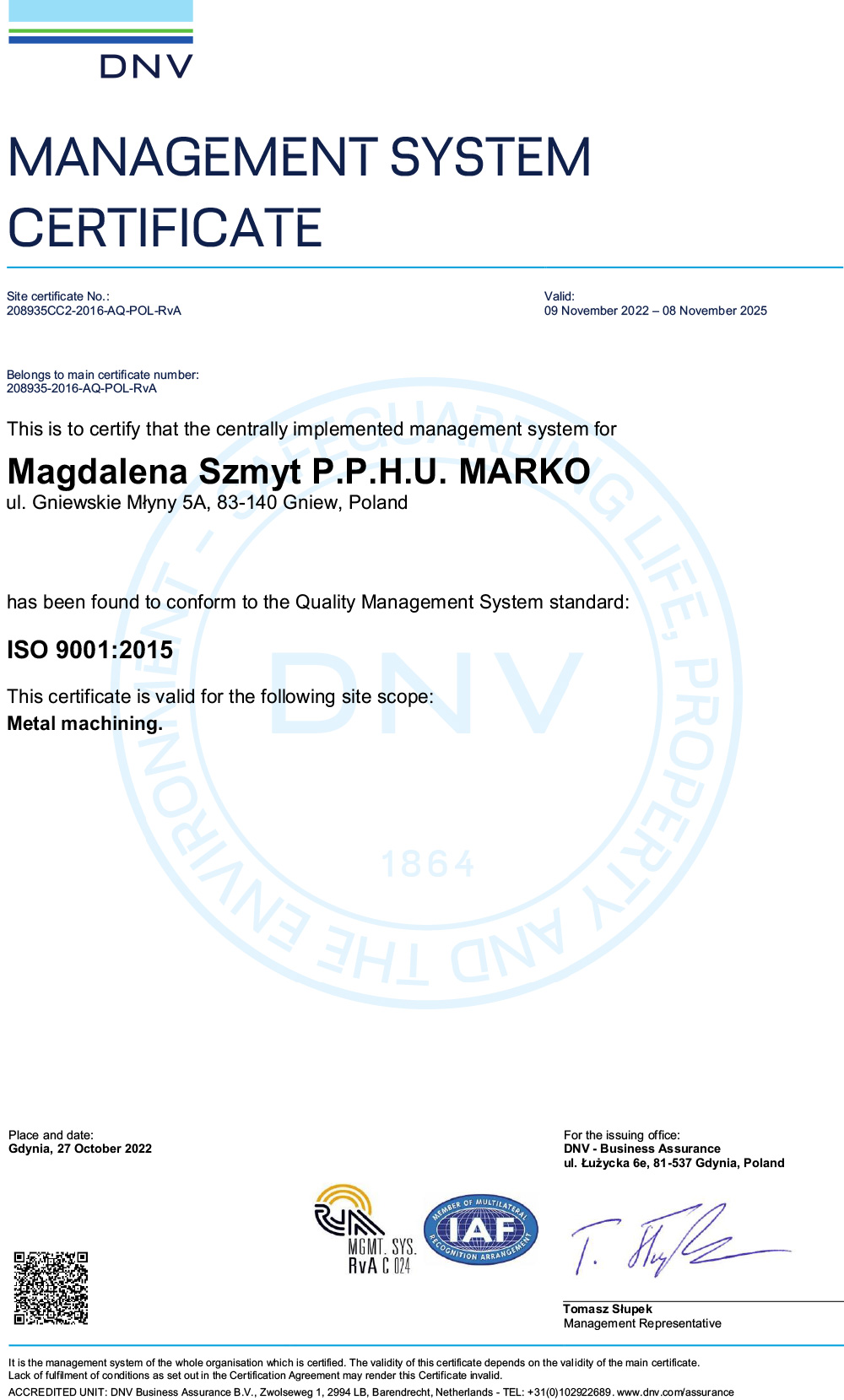

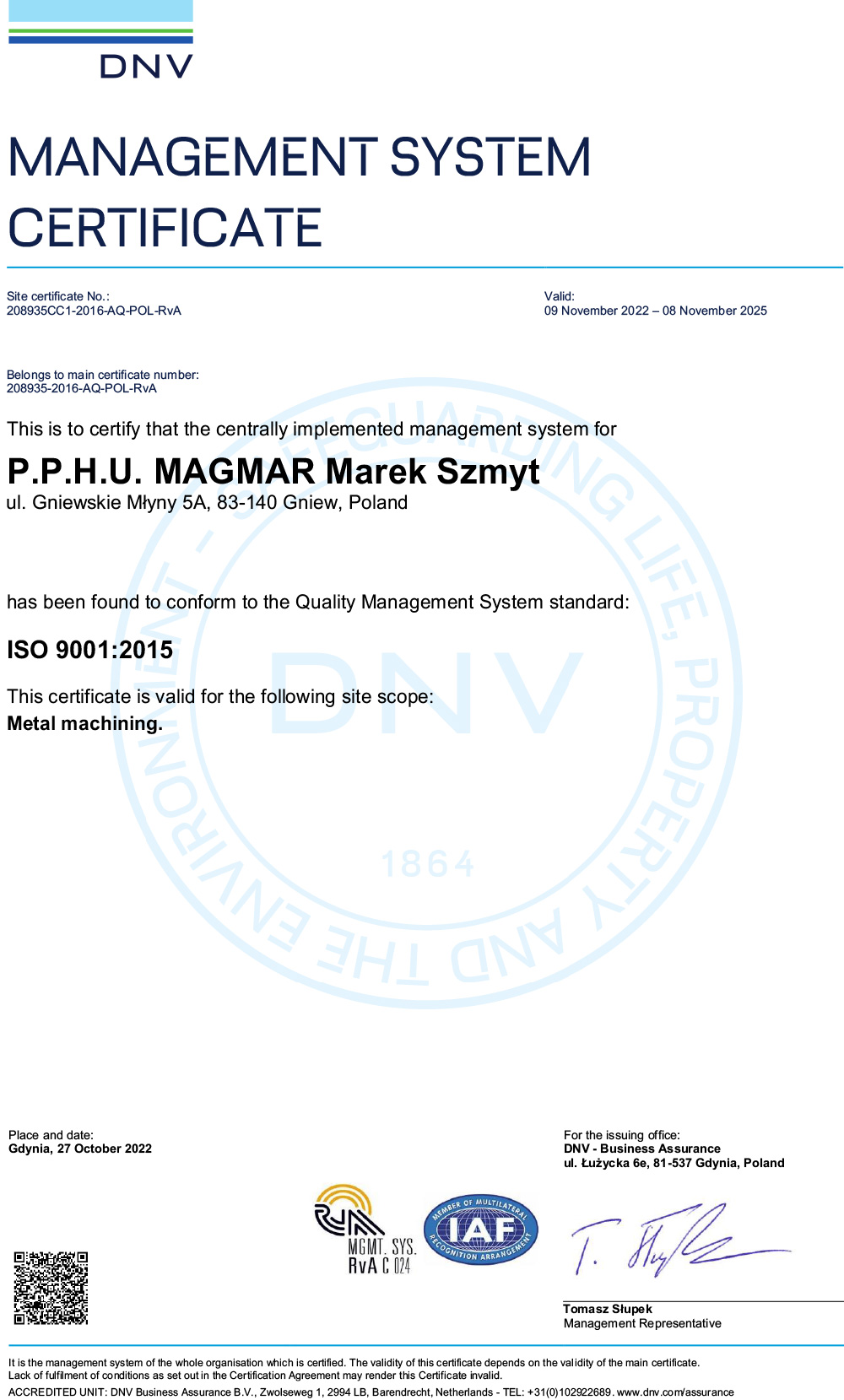

Certificates and awards

In November 2010 we successfully passed certified audit of Quality Management System, carried out by DNV GL, in accordance with the requirements of ISO 9001.

In the year 2013 we took part in the prestigious competition of the State Labour Inspectorate “Employer – safe work’s organizer”. We took honorable 2nd place in the category of employers with up to 50 employees. It allowed us to be one of the group of entrepreneurs who are building their business success not only on production indicators and efficient management, but also on extra attention to safety at work.